You’re powering industrial inspections with Intel’s advanced cameras, where AI algorithms analyze data in real time to detect defects, slashing downtime by up to 50%. High-resolution imaging captures subtle flaws with exceptional accuracy, while seamless integration into your existing systems boosts efficiency and minimizes disruptions. Predictive maintenance anticipates issues, optimizing workflows through data-driven insights. Discover how these capabilities can further transform your operations for greater productivity.

Advanced AI Capabilities in Intel’s Cameras

Intel’s cameras leverage advanced AI to revolutionize industrial inspections, allowing you to detect defects with unprecedented accuracy and speed. Through sophisticated AI algorithms, these systems analyze vast data streams in real time, giving you the freedom to identify issues before they escalate. You’ll find that camera integration with existing workflows is seamless, enhancing your operational autonomy by automating routine checks. This means you’re not bogged down by manual processes; instead, AI algorithms empower you to make informed decisions quickly, boosting productivity without oversight burdens. By prioritizing efficiency, Intel’s cameras let you reclaim time for innovation, ensuring that every inspection cycle runs smoothly and reliably. In this setup, you’re in control, with technology adapting to your needs rather than dictating them, fostering a liberated approach to quality assurance. Ultimately, this integration transforms how you maintain standards, making industrial oversight more intuitive and effective.

High-Resolution Imaging for Precision Inspections

You can achieve enhanced image quality with Intel’s high-resolution cameras, allowing you to spot even the tiniest defects in industrial components. This leads to more accurate precision detection methods that analyze details with greater reliability, reducing errors in your inspections. As you explore industrial imaging applications, you’ll see how these features boost efficiency in sectors like manufacturing and quality control.

Enhanced Image Quality

High-resolution imaging has revolutionized precision inspections by capturing intricate details that enhance defect detection. You’ll find that Intel’s cameras deliver exceptional color accuracy, ensuring colors appear true and consistent, which empowers you to identify subtle defects in materials or products without second-guessing. This precision frees you from unreliable visuals, letting you focus on what matters most. Furthermore, the dynamic range captures a wide spectrum of light and dark areas, revealing hidden flaws in challenging environments. You can analyze scenes with clarity, transforming your inspections into efficient, error-free processes. By integrating these features, you’re not just seeing more—you’re gaining the freedom to make faster, more informed decisions, boosting productivity while minimizing downtime. This approach keeps your operations agile and reliable.

Precision Detection Methods

As industries evolve, precision detection methods leverage high-resolution imaging to pinpoint defects with remarkable accuracy, transforming routine inspections into highly reliable processes. You’ll find that image recognition plays a pivotal role, allowing you to swiftly identify irregularities in real-time, so you’re always one step ahead. By integrating defect analysis, Intel’s cameras enable you to dissect images at a microscopic level, revealing flaws that escape the human eye. This analytical approach frees you from guesswork, empowering your operations with data-driven insights. Imagine streamlining your workflow without compromising quality—you gain the liberty to innovate, reduce downtime, and maintain peak efficiency, all while minimizing risks. Ultimately, these methods put control back in your hands, fostering a seamless path to excellence.

Industrial Imaging Applications

Industrial imaging applications build directly on precision detection by applying high-resolution imaging to everyday inspections, where it delivers crystal-clear visuals that let you spot minute defects in manufacturing lines. With Intel’s advanced cameras, you’re empowered to integrate thermal imaging, revealing heat anomalies that traditional methods miss, giving you the freedom to conduct remote inspections from anywhere—whether you’re overseeing a sprawling factory or a distant site. This analytical approach enhances accuracy, as high-res imagery analyzes patterns in real-time, minimizing downtime and boosting efficiency. You’ll appreciate how it liberates your workflow, letting you make informed decisions without being tethered to the floor, ultimately driving productivity while maintaining exceptional quality control.

Applications in Manufacturing and Warehouses

You can see how Intel’s cameras transform manufacturing line uses by enabling real-time defect detection that boosts your production efficiency and quality control. In warehouse operations, they’ll help you streamline inventory tracking and automate safety checks, reducing errors and downtime. As you explore these applications, consider how integrating such technology could optimize your industrial workflows for greater precision and reliability.

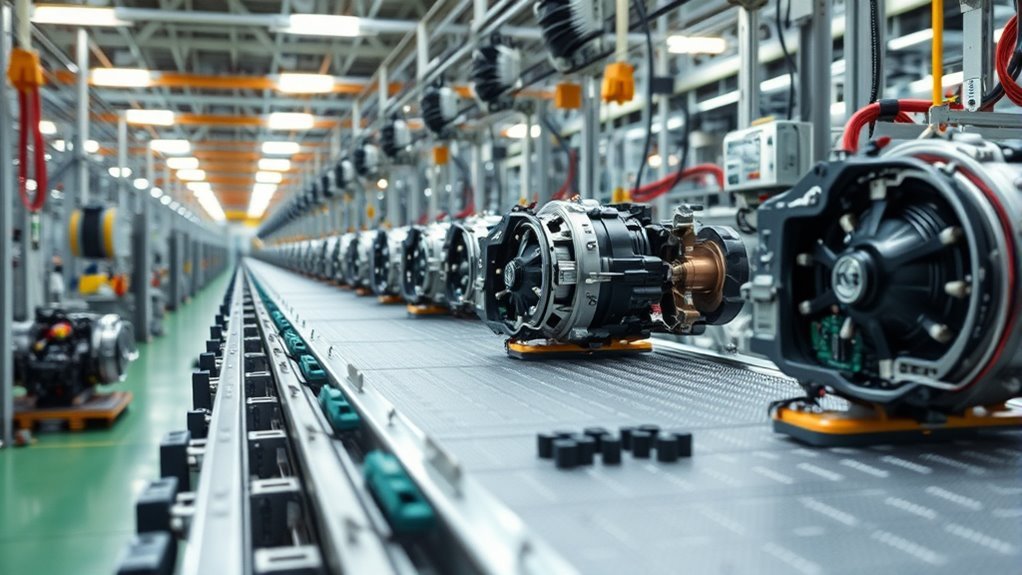

Manufacturing Line Uses

In manufacturing and warehouses, Intel’s cameras revolutionize inspection processes by integrating AI-driven analytics that detect defects and guarantee quality control. You’ll find that these cameras streamline your manufacturing line uses by enhancing inspection workflows with automated quality checks, allowing real-time flaw detection without halting production. This empowers you to break free from outdated manual methods, giving you the liberty to optimize operations and innovate faster. By analyzing vast data streams, Intel’s tech guarantees precision in every step, minimizing errors and waste while boosting throughput. You’re not just inspecting; you’re transforming your line into a smart, adaptive system that adapts to your needs, fostering efficiency and reliability in a dynamic environment. This freedom lets you focus on growth, not grunt work.

Warehouse Operation Applications

Beyond the assembly line, Intel’s cameras transform warehouse operations by deploying AI-powered analytics for seamless inventory tracking and security. You’ll discover that automated inventory streamlines your stock management, using AI to track items in real-time, reduce discrepancies, and predict restocks with pinpoint accuracy—this frees you from tedious manual checks, letting you reclaim valuable time. In a fast-paced environment, these cameras also guarantee safety compliance by monitoring for hazards like obstructed pathways or improper handling, alerting you instantly to maintain a secure workspace without constant supervision. Analytically, this integration boosts efficiency, cutting costs and minimizing risks, so you can operate with greater autonomy. By empowering your decisions with data-driven insights, Intel’s solutions help you build a flexible, innovative warehouse that adapts to your needs, enhancing overall freedom in operations.

Integration With Existing Industrial Systems

As Intel’s cameras introduce advanced imaging capabilities, seamlessly integrating them into your existing industrial systems becomes essential for maximizing efficiency. You’ll appreciate how Intel prioritizes system compatibility, ensuring their cameras work flawlessly with your setups, from legacy machinery to modern networks. This seamless integration frees you from cumbersome upgrades, letting you enhance operations without disruption, empowering your workflow to adapt and thrive.

| Before Integration | After Seamless Integration |

|---|---|

| Locked into outdated systems, feeling trapped by inefficiencies | Liberated to innovate, with cameras boosting your control and speed |

| Constant compatibility headaches, stirring frustration | Effortless harmony, evoking a sense of freedom and confidence |

| Wasted time on manual tweaks, breeding stress | Streamlined processes, igniting excitement for peak performance |

| Limited scalability, constraining your ambitions | Expanded possibilities, where your vision drives growth unchained |

Enhancing Equipment Monitoring and Maintenance

Intel’s cameras transform equipment monitoring and maintenance by delivering real-time insights that help you spot issues before they escalate. With integrated sensor technologies, you’ll gain precise data on equipment health, empowering you to act freely without downtime surprises. Predictive analytics further enhances this by analyzing patterns, giving you the tools to anticipate failures and optimize schedules on your terms.

- Harness predictive analytics: Forecast potential breakdowns by processing vast data streams, so you maintain control over operations.

- Utilize advanced sensor technologies: Capture detailed visuals and metrics in real time, allowing you to detect subtle anomalies that traditional methods miss.

- Achieve proactive maintenance: Combine these capabilities to schedule interventions efficiently, freeing you from reactive fixes and ensuring seamless productivity.

Driving Data-Driven Decisions for Operational Efficiency

By analyzing the data from Intel’s cameras, you can transform operations through informed decisions that boost efficiency. With data analytics at your fingertips, you’re empowered to refine operational strategies, identifying bottlenecks and optimizing workflows for a more agile setup. This freedom lets you break free from outdated methods, turning raw insights into actionable plans that minimize waste and maximize output.

Imagine harnessing these tools to drive real change—here’s how:

| Operational Strategy | Data Analytics Benefit |

|---|---|

| Real-time monitoring | Instant anomaly detection |

| Predictive maintenance | Proactive issue resolution |

| Resource allocation | Data-driven cost savings |

| Process optimization | Enhanced productivity metrics |

| Scalability planning | Adaptive growth without disruptions |

As you integrate these strategies, you’ll gain the autonomy to innovate, ensuring your operations run smoother and more efficiently than ever. This approach not only streamlines decisions but also fosters a liberated, forward-thinking environment. (148 words)

Frequently Asked Questions

How Much Do Intel’s Cameras Cost?

You’re diving into the murky waters of camera pricing, wondering how much Intel’s cameras cost. You’ll find that prices vary widely, from a few hundred dollars for basic models to several thousand for advanced ones, depending on features. In a competitive analysis, Intel’s offerings often undercut rivals like Sony or Canon, giving you the freedom to choose cost-effective, high-quality options without breaking the bank. Stay informed!

Where Can I Purchase Intel’s Cameras?

You’re wondering where you can purchase Intel’s cameras, so let’s explore your purchasing options. You’ll find them through Intel’s official website, authorized retailers like Amazon or Best Buy, and industrial suppliers. Don’t forget to review camera specifications like resolution and sensor types to match your needs. This empowers you to choose freely, ensuring peak performance for your projects. Compare deals for the best value.

What Is the Warranty Period for Intel’s Cameras?

You’re wondering about the warranty period for Intel’s cameras, and it’s key to understanding their reliability. When exploring warranty details, you’ll discover Intel typically offers a one-year standard warranty, covering defects and ensuring camera reliability for your industrial needs. This gives you the freedom to invest confidently, knowing support’s there if issues arise, enhancing your operational independence. Always check official sources for specifics.

How Do I Contact Support for Intel’s Cameras?

You’re wondering how to contact support for Intel’s cameras, right? For camera troubleshooting, immerse yourself in their support resources first—these include online guides, FAQs, and forums to empower your fixes. Once you’ve explored those, reach out via Intel’s website chat, email support@intel.com, or call the helpline. It’s your freedom to resolve issues quickly and get back to seamless operations. Stay analytical and engaged!

Are There Discounts for Bulk Orders of Intel’s Cameras?

You’re wondering if there are discounts for bulk orders of Intel’s cameras. Absolutely, Intel offers attractive bulk pricing options and exclusive camera deals that can slash costs for large purchases. This analytical strategy empowers you with the freedom to scale operations affordably, letting you choose what’s best without financial constraints. It’s all about maximizing value while maintaining your independence in tech decisions.