To identify materials used in drone construction, examine each component such as frames, housings, and propellers. Common materials include carbon fiber for its superior strength-to-weight ratio, lightweight plastics for cost-effectiveness, and aluminum for its durability and heat dissipation. Steel may be present for structural integrity, while foams enhance impact resistance. Understanding these materials is essential for evaluating a drone’s performance. Continue exploring to uncover more about the innovations in drone material technology and their implications.

Overview of Drone Construction Materials

When considering drone construction materials, it is crucial to understand how each component contributes to the overall performance and functionality of the device. The choice of materials directly impacts drone design, influencing weight, durability, and flight capabilities. Common materials include plastics, metals, and composites, each offering unique benefits. For instance, lightweight plastics enhance agility while metals provide robustness. Material innovation continues to shape the industry, introducing advanced composites that optimize strength-to-weight ratios. This evolution of materials allows for more efficient designs, catering to a variety of applications, from recreational to commercial uses. By grasping the significance of these materials, you can appreciate how they affect your drone’s operation and guarantee it meets your performance expectations. Understanding these factors empowers your freedom in selecting the right drone. Additionally, European brands prioritize sustainable materials in their designs, enhancing both environmental responsibility and product longevity.

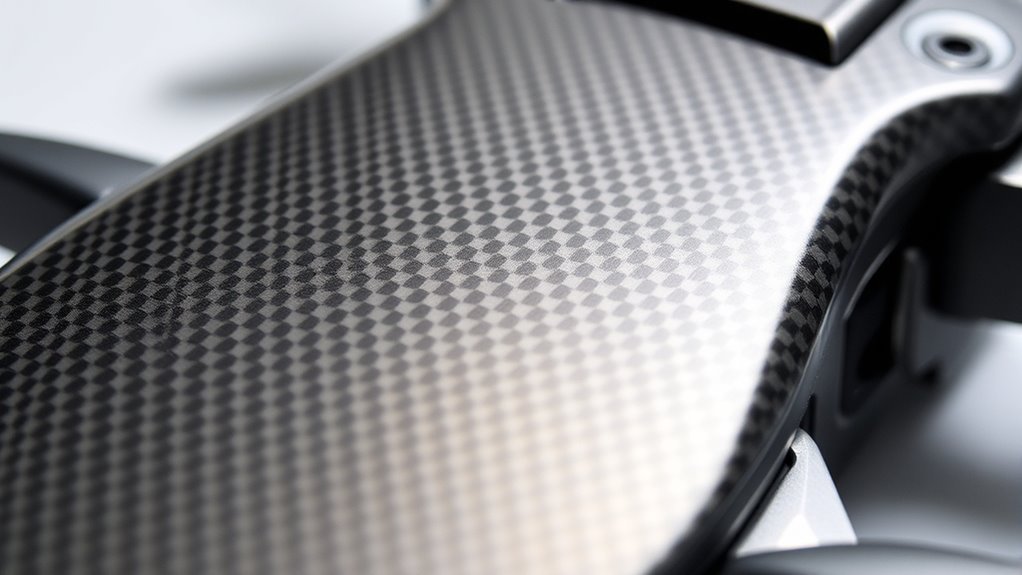

Carbon Fiber: Strength and Lightweight Properties

Carbon fiber is a material that stands out for its exceptional strength-to-weight ratio, making it a preferred choice in drone construction. In your pursuit of advanced drone design, understanding carbon fiber applications is vital. This composite material’s lightweight properties enhance flight efficiency, allowing for longer battery life and improved maneuverability. Carbon fiber innovations have led to the development of frames that are not only robust but also resistant to environmental stressors, contributing to longevity and reliability. When selecting materials, consider how carbon fiber’s unique characteristics can optimize your drone’s performance, ensuring it meets your specific needs. As you explore drone construction, leveraging carbon fiber will empower you to achieve the freedom and flexibility you desire in aerial technology.

Plastic Components: Versatility and Cost-Effectiveness

When considering drone design, plastic components offer significant advantages in weight reduction and structural integrity. Their lightweight nature contributes to enhanced flight efficiency, while cost-effective manufacturing processes make them an attractive option for mass production. This combination of benefits positions plastics as an essential material in modern drone construction.

Lightweight Structural Benefits

Although many materials are utilized in drone construction, plastic components stand out for their lightweight structural benefits, offering a unique combination of versatility and cost-effectiveness. By incorporating plastics, you can achieve a lightweight design that enhances flight performance and extends battery life. Consider these advantages:

- High Strength-to-Weight Ratio: Plastics provide durability without the bulk.

- Design Flexibility: Easily molded into complex shapes for structural optimization.

- Corrosion Resistance: Reduces maintenance needs, enhancing longevity.

- Damping Properties: Minimizes vibrations, improving stability during flight.

These characteristics empower you to create innovative drone structures, maximizing efficiency while maintaining affordability. Embracing plastic components not only promotes a lightweight design but also paves the way for creative engineering solutions in drone technology.

Cost-Effective Manufacturing Processes

Cost-effective manufacturing processes are essential for optimizing the production of plastic components in drones. By embracing sustainable sourcing practices, you can greatly reduce costs while minimizing environmental impact. Material innovations, such as advanced thermoplastics and bioplastics, offer not only durability but also versatility in design, allowing for complex shapes without compromising strength. Techniques like injection molding and 3D printing enable efficient production runs, adapting to varying demands without extensive retooling expenses. These processes not only enhance production speed but also align with your goals of reducing waste and promoting sustainability. Ultimately, integrating these cost-effective methods guarantees that you maintain a competitive edge in the drone industry while promoting freedom through innovative, eco-friendly solutions.

Aluminum: Durability and Heat Dissipation

Aluminum, known for its exceptional durability and effective heat dissipation properties, is a favored material in drone manufacturing. Utilizing aluminum alloys enhances the overall performance, allowing drones to withstand various operational stresses. Here are key benefits of aluminum in drones:

Aluminum’s durability and heat dissipation make it an ideal choice for enhancing drone performance under operational stresses.

- Lightweight: Reduces overall drone weight, improving flight efficiency.

- High thermal conductivity: Effectively dissipates heat generated during operation, preventing overheating.

- Corrosion resistance: Guarantees longevity, even in harsh environmental conditions.

- Ease of fabrication: Allows for complex designs and quick assembly.

Steel: Structural Integrity and Weight Considerations

When considering steel for drone construction, you need to assess its strength-to-weight ratio, which directly impacts flight performance. Corrosion resistance is another critical factor, as exposure to various environments can degrade structural integrity over time. Additionally, understanding the manufacturing techniques used can influence both the cost and effectiveness of steel components in drone design.

Strength-to-Weight Ratio

Although steel is renowned for its structural integrity, its weight can pose challenges in drone design, particularly when optimizing the strength-to-weight ratio. In material science, evaluating this ratio is vital for enhancing drone performance and efficiency. Here are key considerations:

- Load-Bearing Capacity: Understand how much weight your drone can carry without compromising flight stability.

- Material Alternatives: Explore lightweight composites or aluminum that might offer better ratios than steel.

- Design Innovations: Incorporate hollow structures or reinforcements to maximize strength while minimizing weight.

- Performance Testing: Conduct rigorous tests to determine how various materials affect your drone’s agility and endurance.

Corrosion Resistance Factors

While steel’s structural integrity makes it a popular choice in drone construction, its susceptibility to corrosion can greatly impact performance and longevity. Understanding corrosion resistance factors is essential for maintaining material longevity in drones. Here’s a concise overview:

| Corrosion Factor | Description | Impact on Drones |

|---|---|---|

| Environmental Exposure | Humidity and salt can accelerate corrosion | Shortens lifespan and reliability |

| Protective Coatings | Use of paints or galvanization | Enhances corrosion resistance |

| Alloy Composition | Adding elements like chromium | Improves overall material longevity |

| Maintenance Practices | Regular inspections and cleaning | Prevents corrosion buildup |

| Design Considerations | Avoiding moisture traps | Reduces corrosion risk |

Manufacturing Techniques Overview

As manufacturers seek to optimize drone performance, understanding the interplay between steel’s structural integrity and weight factors becomes essential. Effective drone design hinges on balancing these elements. Here are key aspects to take into account:

- Material Selection: Choosing the right grade of steel can greatly impact strength and weight.

- Fabrication Techniques: Innovations like laser cutting and 3D printing allow for precise manufacturing, enhancing structural integrity while minimizing excess weight.

- Weight Distribution: Strategic placement of steel components can improve flight stability and maneuverability.

- Reinforcement Methods: Techniques like heat treatment can strengthen steel without adding weight, ensuring durability.

Foam and Composite Materials: Impact Resistance

When designing drones, understanding the impact resistance of foam and composite materials is essential for ensuring durability and performance. Different foam types, such as polyethylene and polyurethane, offer various levels of impact resistance, while composites combine materials to enhance strength without adding bulk.

| Material Type | Impact Resistance |

|---|---|

| Polyethylene Foam | Moderate |

| Polyurethane Foam | High |

| Carbon Fiber | Very High |

| Glass Fiber | High |

| EPS (Expanded Polystyrene) | Moderate |

Utilizing these materials not only improves the drone’s ability to withstand collisions but also contributes to overall weight reduction, a critical factor in flight efficiency. Understanding these aspects helps you make informed choices for your drone’s design.

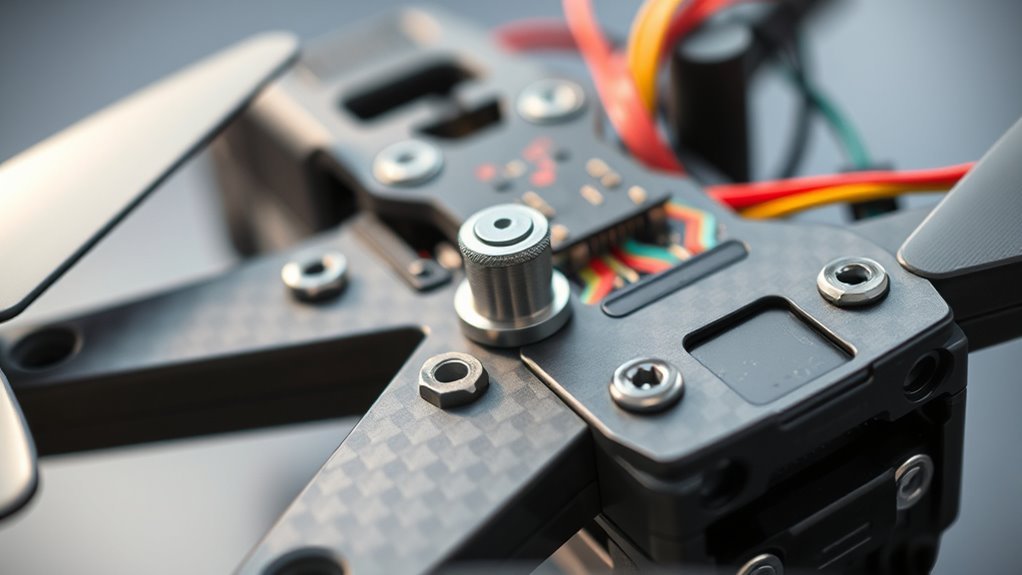

Electronics Housing: Protecting Sensitive Components

Ensuring the safety of sensitive electronic components in drones is essential, especially since these elements are vulnerable to environmental factors and mechanical stress. Proper electronics housing not only protects these components but also adheres to safety standards, reducing the risk of failure during operation. Here are four key considerations for effective electronics housing:

- Material Selection: Choose lightweight, durable materials that resist corrosion and impact.

- Sealing Techniques: Implement effective sealing methods to protect against moisture and dust.

- Thermal Management: Design for heat dissipation to prevent overheating of components.

- Environmental Impact: Use eco-friendly materials to minimize the environmental footprint while ensuring safety.

Propeller Materials: Balancing Performance and Weight

Electronics housing plays an essential role in drone performance, but equally important is the choice of materials for propellers, which directly affect flight efficiency and maneuverability. When considering propeller design, you’ll find that materials like carbon fiber, plastic, and wood each offer unique benefits and drawbacks. Carbon fiber provides exceptional strength-to-weight ratios, enhancing performance enhancement, while plastic is lightweight and cost-effective, though less durable. Wood, often favored for its aesthetic appeal, can offer reasonable performance but may lack in longevity. Balancing weight and performance is vital; a heavier propeller can hinder agility, while an overly light option might compromise stability. Ultimately, the right material choice must align with your specific flight goals and desired capabilities for ideal drone operation.

Future Trends in Drone Material Technology

As advancements in drone technology continue to evolve, the materials used in their construction are also undergoing significant transformation. Future innovations in drone materials focus on enhancing performance while ensuring material sustainability. Here are key trends to watch:

- Biodegradable materials: Drones will increasingly use eco-friendly composites that minimize environmental impact.

- Lightweight alloys: New metal combinations will optimize strength-to-weight ratios, enhancing flight efficiency.

- Smart materials: Integrating sensors into materials will allow real-time monitoring of structural integrity.

- Nanomaterials: These will improve durability and performance, enabling drones to operate in harsher environments. Additionally, advancements in sustainable materials will promote eco-friendliness without compromising strength.

Frequently Asked Questions

What Materials Are Best for Specific Drone Applications?

When you seek the perfect materials for drones, consider carbon fiber for its unmatched strength and aerodynamic efficiency, and foam composites for exceptional weight reduction. Each choice can elevate your drone’s performance to unparalleled heights.

How Do Weather Conditions Affect Drone Material Performance?

Weather conditions greatly impact material durability, affecting drones’ performance. You’ll find that enhanced weather resistance in materials leads to better resilience against rain, wind, and temperature fluctuations, essential for maintaining operational efficiency in varying environments.

Can Recycled Materials Be Used in Drone Construction?

Did you know that using recycled plastics can reduce drone manufacturing’s carbon footprint by up to 30%? Eco-friendly composites not only enhance sustainability but also maintain structural integrity, proving valuable for future drone construction.

What Is the Cost Difference Between Material Types for Drones?

When performing a cost analysis, you’ll find significant differences in material sourcing for drones. Lightweight composites might be pricier but offer durability, while traditional plastics are cheaper yet can compromise performance. Consider long-term benefits versus initial costs.

How Do Material Choices Influence Drone Battery Life?

Material choices greatly impact battery life. By optimizing weight through advanced materials, you can enhance battery chemistry efficiency, leading to longer flight durations. Balancing these factors is essential for maximizing performance and achieving your desired operational freedom.