To make drones, start with conceptualizing and designing your model, focusing on functionality and user experience. Next, select high-quality components, including motors and controllers. Move on to prototyping, making certain to visualize the design digitally. Develop software to support operations and integration. After assembly, implement rigorous quality control and conduct thorough testing. Finally, guarantee compliance with regulations before launching to the market. Each of these steps is critical for achieving a reliable drone system, leading to further insights on the process.

Conceptualization and Design

When initiating the journey of drone creation, the first step is conceptualization and design, which can be broken down into three critical phases. First, you’ll engage in creative brainstorming to generate innovative ideas, focusing on functionality, aesthetics, and user experience. This phase encourages you to explore various concepts without limitations. Next, you’ll apply design principles to refine your ideas, ensuring they meet requirements for aerodynamics, stability, and usability. This analytical approach helps you identify potential challenges early in the process. Additionally, understanding common manufacturing locations can provide insights into the selection of materials and components. Finally, you’ll create initial sketches or digital models, allowing you to visualize the drone’s structure and components. By embracing this structured yet creative process, you’ll lay a solid foundation for successful drone development that embodies your vision of freedom. Additionally, selecting the essential drone components early in the design phase can significantly enhance the drone’s performance and reliability.

Component Selection

When selecting components for your drone, you’ll need to focus on essential parts like motors, flight controllers, and batteries. Quality of materials also plays a critical role in ensuring performance and durability. Choosing the right combination can greatly impact your drone’s efficiency and reliability, especially when considering factors like flight time and battery performance. Additionally, selecting brushless motors can enhance propulsion efficiency, contributing to longer flight durations.

Essential Drone Parts

Selecting the essential components for a drone is critical to its performance and functionality. You’ll need to choose efficient drone motors that match your desired speed and thrust. A reliable flight controller is essential for stabilizing your drone and managing its flight path. Consider battery systems that provide adequate power while maintaining a lightweight design. If you plan on camera integration, make sure your setup can support the payload capacity you require. Incorporate navigation sensors for enhanced autonomy and communication modules for remote operation. Frame materials should be durable yet lightweight, while propeller types affect aerodynamics. Don’t overlook safety features and establish maintenance protocols. Finally, refer to user manuals for guidance on assembly and operation. This careful selection guarantees a successful drone build.

Material Quality Considerations

The choice of materials for drone components greatly influences overall performance and durability. You need to prioritize material durability while balancing weight optimization to enhance flight efficiency. Conduct a thorough cost analysis to guarantee that the selected materials fit within your budget without compromising quality. Always evaluate supplier reliability, as dependable sourcing is essential for maintaining consistent manufacturing standards. Consider the environmental impact of the materials you choose; sustainable options can improve your drone’s market appeal. By integrating high-quality materials with an eye toward performance, cost, and environmental responsibility, you can create drones that not only meet user expectations but also stand out in a competitive landscape. Make informed choices to guarantee your drone excels in functionality and longevity.

Prototyping

Prototyping serves as a crucial phase in the drone development process, allowing you to transform theoretical designs into tangible models. Utilizing 3D modeling software, you can create accurate representations of your drone’s components, ensuring they fit together seamlessly. This step not only visualizes your concept but also aids in identifying potential design flaws early on. Through iterative feedback, you can refine your prototype based on tests and evaluations, enhancing functionality and performance. Each iteration brings you closer to the final product, enabling you to make informed decisions about materials and configurations. By embracing prototyping, you empower yourself to innovate and adapt, fostering a sense of freedom in your design process while maintaining technical precision. Furthermore, integrating swarm technology during the prototyping phase can significantly enhance the coordination capabilities of your drone.

Software Development

Once you’ve refined your drone prototype, the next step focuses on software development, which is essential for translating your design into a fully functional system. You’ll need to establish a robust software architecture that supports the drone’s capabilities, guaranteeing efficient data processing and control. This involves selecting appropriate programming languages and frameworks that align with your hardware specifications.

Simultaneously, designing an intuitive user interface is vital for operational ease. The interface should provide real-time feedback and enable seamless interaction with the drone. By prioritizing functionality and user experience, you empower operators to maximize the drone’s potential. Balancing these elements will not only enhance performance but also guarantee you retain the freedom to innovate and customize your drone’s features as needed.

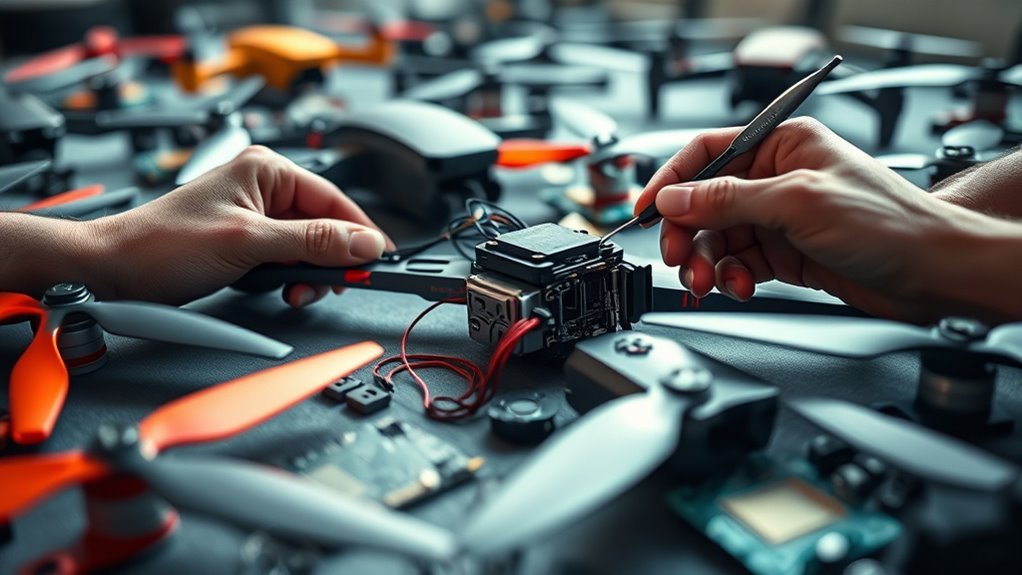

Assembly

Begin assembling your drone by carefully organizing all components and tools to guarantee an efficient workflow. Utilize various assembly techniques, such as modular construction and systematic wiring, to streamline the process. Ascertain you’re familiar with the specifications of each part, as this knowledge aids in overcoming potential assembly challenges. Pay close attention to alignment and secure connections; any oversight can lead to performance issues. It’s essential to double-check each component’s compatibility, especially when integrating software and hardware elements. Additionally, regular inspections of the components during assembly can help identify any issues that might affect performance. As you progress, maintain a clean workspace to minimize distractions and mistakes. Remember, thorough documentation of your assembly steps can facilitate troubleshooting and future upgrades, embodying the freedom to modify and enhance your drone as technology evolves. Additionally, consider incorporating advanced stabilization algorithms to improve flight performance and reliability during assembly.

Quality Control

In quality control, you’ll need to implement rigorous inspection procedures to guarantee every component meets specified standards. This involves detailed checks at multiple stages of production to identify and rectify defects. Additionally, adhering to established testing standards is essential for validating the drone’s performance and reliability. Furthermore, integrating advanced data processing capabilities can enhance the efficiency of quality control processes, allowing for quicker identification of potential issues. Incorporating predictive maintenance strategies can also significantly reduce unexpected breakdowns, ensuring smoother operations throughout the production process.

Inspection Procedures

While developing drones, rigorous inspection procedures are essential to guarantee quality control and performance reliability. You need to implement various inspection techniques, such as visual assessments and non-destructive testing, to identify potential defects early in the production process. Utilizing advanced inspection tools, like ultrasonic and thermal imaging devices, allows you to detect structural weaknesses that might compromise drone integrity. Additionally, maintaining a checklist for each component assures consistency and thoroughness throughout the inspection process. It’s imperative to document all findings meticulously, as this data can help refine manufacturing practices and improve future designs. Ultimately, these systematic inspection procedures are critical for making sure your drones meet the high standards expected in the industry, empowering you to deliver reliable and high-performing products.

Testing Standards

After establishing robust inspection procedures, the next step is to adhere to stringent testing standards to guarantee the drones meet quality control benchmarks. You’ll want to implement various testing methodologies, including functional tests, endurance trials, and environmental assessments. Each method evaluates different aspects of performance, ensuring reliability and safety. Establish clear performance benchmarks that your drones must meet, such as flight time, payload capacity, and maneuverability. By systematically analyzing data from these tests, you can identify potential weaknesses and areas for improvement. This rigorous approach not only enhances the quality of your drones but also instills confidence in your end users, allowing them the freedom to operate without concerns about reliability or performance failures.

Testing and Validation

Testing and validation are essential phases in the drone development process, ensuring that the design meets performance specifications and regulatory requirements. You’ll need to evaluate key performance metrics, focusing on flight stability, reliability, and overall functionality. This process involves rigorous testing under various conditions to gather data and identify any weaknesses in your design. Additionally, incorporating advanced battery technology can significantly improve flight time optimization in your drone’s performance. A thorough assessment of the advanced obstacle avoidance system is vital to ensure safe operation during dynamic flight conditions.

| Test Type | Objective | Expected Outcome |

|---|---|---|

| Stability Test | Assess drone’s flight stability | Consistent hovering and maneuverability |

| Endurance Test | Measure battery life | Extended flight duration |

| Payload Test | Evaluate load capacity | Safe transport of designated weight |

| Range Test | Determine operational range | Effective control at distance |

Regulatory Compliance

Steering through regulatory compliance is vital for any drone development project, as it guarantees your UAV adheres to legal standards and safety protocols. Understanding the various regulatory frameworks in your region is significant; they dictate airspace usage, operational limitations, and certification requirements. Be prepared to face compliance challenges, such as maneuvering differing regulations across jurisdictions or adapting to evolving laws. Staying informed about updates from aviation authorities can help mitigate risks. Additionally, consider implementing robust documentation practices to streamline the compliance process. By prioritizing regulatory adherence, you not only secure your drone’s legality but also enhance its marketability and operational safety, ultimately allowing you greater freedom to innovate within the constraints of the law.

Market Launch

Successfully steering through regulatory compliance sets the stage for your drone’s entry into the market. Now, it’s essential to conduct a thorough market analysis to identify your target audience. Understanding their preferences, pain points, and behaviors will help you tailor your marketing strategies effectively. Drones equipped with advanced crop monitoring solutions can significantly enhance productivity, which may resonate with potential customers.

| Step | Description |

|---|---|

| Market Research | Analyze competitors and market trends |

| Audience Segmentation | Define customer profiles and needs |

| Marketing Strategy | Develop a plan to reach your target audience |

| Feedback Loop | Gather user feedback for continuous improvement |

Launching your drone involves not just presenting a product, but creating a narrative that resonates with your audience. Focus on showcasing features that enhance their freedom, and you’ll achieve a successful market entry. Additionally, consider incorporating NDAA compliance into your marketing narrative, as it demonstrates your commitment to security and reliability in a competitive landscape.

Frequently Asked Questions

What Materials Are Best for Drone Frames?

When considering materials for drone frames, you’ll find carbon fiber offers superior strength-to-weight ratios, while aluminum alloy provides durability and cost-effectiveness. Choosing between them depends on your specific performance and budget requirements.

How Do I Choose the Right Battery Type?

To choose the right battery type, consider battery chemistry for efficiency and weight, and assess the capacity rating to guarantee adequate flight time. Balancing these factors optimizes performance and enhances your drone’s operational freedom.

What Are Common Drone Manufacturing Challenges?

You’ll face common manufacturing challenges like supply chain disruptions and regulatory hurdles. Maneuvering through these issues requires strategic planning and adaptability, ensuring your drone production remains efficient while meeting compliance standards necessary for market entry.

How Can I Ensure My Drone Is Weather-Resistant?

To guarantee your drone’s weather-resistant, utilize effective drone sealing techniques and apply waterproof coatings. This’ll protect sensitive components from moisture, enhancing durability and maintaining performance in various environmental conditions, allowing you to explore freely.

What Trends Are Influencing Drone Technology Advancements?

You’ll find trends like autonomous navigation and AI integration are shaping drone technology. These advancements enhance efficiency, expand operational capabilities, and offer greater freedom in various applications, from delivery services to agricultural monitoring. Embrace the evolution.