To guarantee peak performance of engineer turrets, you’d need to focus on compatible motor types, propellers, and power systems. Brushless DC motors are ideal for heavy payloads, while propeller size influences lift efficiency. Lithium Polymer batteries enhance power efficiency, essential for rapid response. Software and control systems should integrate seamlessly for real-time data processing. Be aware of maintenance needs to prevent operational failures. If you consider these aspects, you’ll uncover more details about spare drone part compatibility.

Understanding Engineer Turrets and Their Functionality

Engineer turrets are advanced defensive structures designed to enhance the security of various installations. Their turret design integrates multiple layers of technology, providing a robust barrier against potential threats. Each turret’s functionality revolves around its ability to detect, track, and neutralize intrusions effectively. Utilizing high-precision sensors and automated targeting systems, these turrets guarantee rapid response times, thereby minimizing vulnerabilities. When you understand the mechanics behind turret design, you can appreciate how these systems maintain operational integrity. The modular architecture allows for easy upgrades and replacements, guaranteeing long-term viability. By harnessing the power of advanced materials and technologies, engineer turrets not only safeguard your assets but also empower your autonomy in an ever-changing environment.

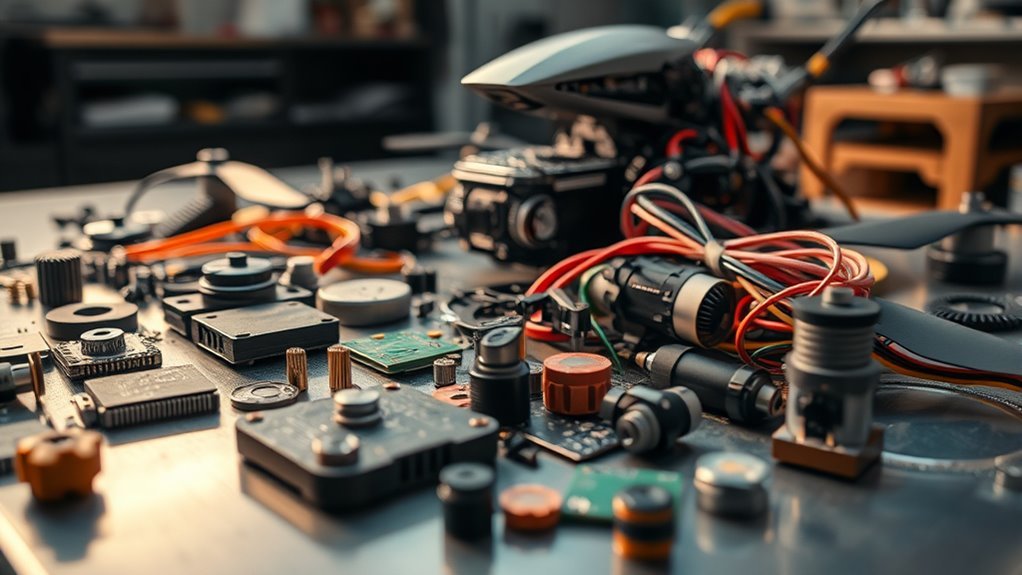

Essential Drone Parts for Compatibility

When selecting spare drone parts for engineer turrets, you’ll need to guarantee compatibility with rotor types and power supply requirements. Different rotor configurations can greatly affect performance, so it’s essential to match them correctly. Additionally, understanding the power supply specifications will prevent functionality issues and optimize overall efficiency. Furthermore, ensuring the aerodynamic design is compatible with the selected parts can enhance flight stability and efficiency. Consider that sub-2 cm horizontal accuracy is crucial for effective surveying applications, which can be influenced by the choice of spare parts.

Compatible Rotor Types

Selecting the right rotor type is essential for guaranteeing best performance and compatibility in drone operations. You’ll want to focus on compatible rotor types that align with your engineer turrets. Consider rotor material considerations carefully; materials like carbon fiber offer strength and reduced weight, while plastic is cost-effective yet less durable. The choice of rotor impacts not only flight efficiency but also overall drone stability. Ascertain your selected rotor types are designed to match the dimensions and specifications of your drone’s mounts. Using incompatible rotors can lead to performance issues or even damage. By understanding these factors, you’ll maximize your drone’s capabilities while enjoying the freedom of reliable aerial operations.

Power Supply Requirements

Verifying your drone’s power supply meets the required specifications is vital for ideal operation and reliability. You need to take into account the power consumption of the engineer turret and its components, as mismatched specifications can lead to suboptimal performance. Confirm that your power supply can handle the load without exceeding its limits; this helps maintain energy efficiency and prolongs the lifespan of your drone. It’s also important to assess the voltage and current ratings of spare parts to guarantee compatibility. Using energy-efficient components can reduce overall power consumption, allowing your drone to operate longer without frequent recharges. A well-matched power supply guarantees your system remains reliable, granting you the freedom to explore and utilize your drone effectively in diverse environments.

Motors and Propellers: Key Components

When selecting motors for your drone turret, you’ll need to guarantee compatibility with the drone’s frame and intended application. Propeller size also plays a vital role in optimizing performance, as it directly affects lift and maneuverability. Additionally, considering performance enhancement options can markedly improve efficiency and responsiveness in various operational scenarios.

Motor Types Compatibility

Understanding motor types compatibility is essential for the best performance of engineer turrets and their associated drones. Selecting the right motors affects motor efficiency and motor torque, key factors in optimizing drone functionality. Here are four critical motor types to evaluate:

- Brushless DC Motors: High efficiency and torque, ideal for heavy payloads.

- Brushed DC Motors: Simple and cost-effective, but lower efficiency.

- Stepper Motors: Excellent for precise control, though torque can vary.

- Servo Motors: Great for applications requiring high torque at low speeds.

Propeller Size Requirements

Selecting the right propeller size is vital for optimizing the performance of engineer turrets and their drones. Propeller efficiency directly influences flight stability and energy consumption. When you’re choosing a propeller, consider size variations that can affect thrust and maneuverability. Smaller propellers typically offer quicker response times, while larger ones can provide greater lift but may draw more power. It’s important to match the propeller size with the motor specifications to guarantee compatibility and prevent overheating. Keep in mind that different missions may require different propeller sizes; consequently, having a selection on hand can maximize versatility. Ultimately, understanding the relationship between propeller size and performance can empower you to make informed decisions that enhance operational capabilities.

Performance Enhancements Options

Although the choice of motors and propellers is critical for enhancing the performance of engineer turrets, it’s important to reflect on how these components work together to influence overall efficiency and capability. To achieve peak performance upgrades, consider these efficiency boosters:

- High-Torque Motors: They provide better lift and responsiveness.

- Lightweight Propellers: Reducing mass improves acceleration and maneuverability.

- Variable Pitch Designs: They allow for dynamic adjustments according to flight conditions.

- High-Efficiency Brushless Motors: They minimize energy loss, maximizing battery life.

Batteries and Power Systems for Engineer Turrets

Batteries and power systems are critical components in the operation of engineer turrets, directly impacting their efficiency and effectiveness. You’ll want to verify you select batteries that maximize battery life and power efficiency, as these factors determine operational longevity and performance under load.

| Battery Type | Power Efficiency |

|---|---|

| Lithium Polymer | High |

| Nickel-Metal Hydride | Moderate |

| Lead-Acid | Low |

Choosing the right battery can enhance the turret’s performance and longevity. Consider the environmental conditions and usage scenarios to select the best option. Upgrading your power systems can result in quicker response times and improved reliability, giving you an edge in critical situations.

Control Systems and Software Integration

Power systems alone won’t guarantee peak performance for engineer turrets; the integration of control systems and software plays a pivotal role in their operation. To guarantee ideal functionality, consider the following aspects:

- Control Algorithms: Tailor these to match your turret’s specific tasks, enhancing accuracy and responsiveness.

- Software Updates: Regularly implement updates to fix bugs and introduce new features, ensuring your system stays cutting-edge.

- Real-time Monitoring: Integrate systems that provide instant feedback on turret performance, allowing for immediate adjustments.

- User Interface: A streamlined interface enables easier control, granting you the freedom to focus on mission objectives without technical distractions.

Moreover, leveraging real-time data processing can significantly enhance the turret’s ability to adapt to changing conditions and improve decision-making.

Maintenance Tips for Optimal Performance

To maintain peak performance of engineer turrets, it’s essential to implement a rigorous maintenance schedule that addresses both mechanical and software components. Regular drone maintenance checks should include inspecting all moving parts for wear and tear, verifying connections are secure, and recalibrating sensors as necessary. Clean the turret’s exterior to prevent dust buildup, which can affect functionality. Additionally, software updates should be performed consistently to enhance performance optimization and security. Monitoring system logs will help identify anomalies early, allowing for timely interventions. Furthermore, advanced features in drone technology can facilitate more efficient maintenance practices. Finally, consider using diagnostic tools to assess overall system health, guaranteeing that your turrets operate at their best. By adhering to these practices, you’ll guarantee longevity and reliability in your engineer turrets. Furthermore, integrating advanced AI integration can significantly streamline maintenance procedures and enhance operational efficiency.

Frequently Asked Questions

Can I Use Parts From Different Drone Brands?

You can’t use parts from different drone brands without considering drone compatibility and brand specifications. Always check the manufacturer’s guidelines to guarantee peak performance and avoid potential malfunctions, maintaining the freedom of seamless operation.

What Tools Are Needed for Replacing Drone Parts?

For drone maintenance, you’ll need tools like screwdrivers, pliers, and a soldering iron. Make certain you have the right tool types for your specific model, as precision is vital for effective and safe part replacement.

How Can I Identify Compatible Spare Parts?

Think of identifying compatible spare parts like solving a complex puzzle. You’ll need to analyze part identification labels and compatibility factors, ensuring each piece fits perfectly to maintain your drone’s performance and reliability.

Are There Universal Spare Parts for Engineer Turrets?

There aren’t universal spare parts for engineer turrets. Each model requires specific components for ideal performance. For efficient engineer turret maintenance, you should always consult your manual to guarantee universal compatibility with available spare parts.

Where Can I Purchase Spare Drone Parts?

You can purchase spare drone parts from online retailers or local hobby shops. These sources often offer a range of components, ensuring you find what you need for your specific project or repair efficiently.